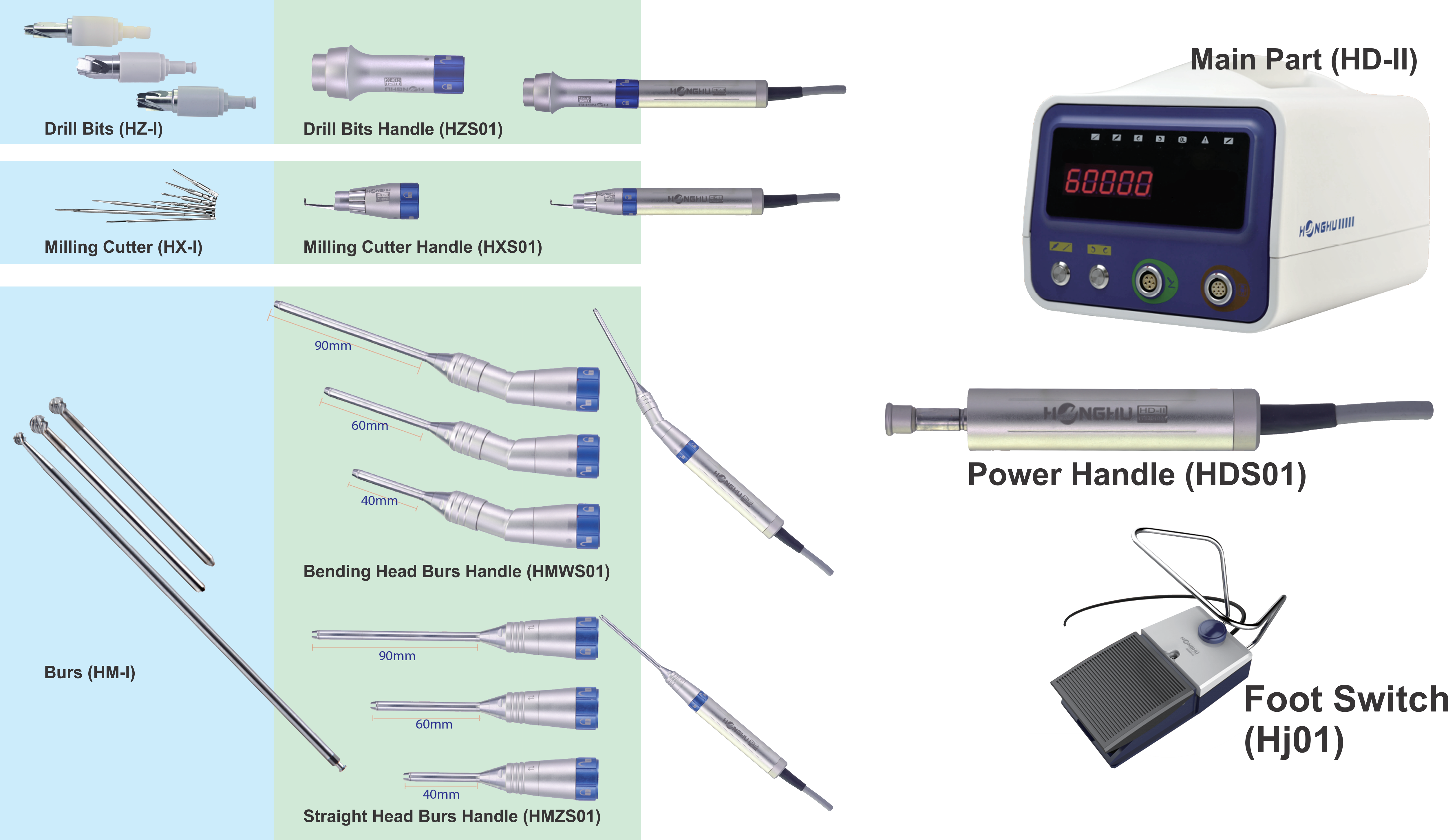

HIGH SPEED DRILL

Multi-purpose Surgical Power Tool system

Designed for neurosurgery Highly increased power and performance High Rotating Speed: 0-60000 rounds Constant torque Quick stop at high speed Rapidly loading and unloading patent

MAIN PART [ HDII ]

◆ The control system uses the high-performance intelligent microprocessor control chip to implement the closed-loop drive control at a constant speed, that is, changes in no-load and full load speeds are within the range of ≤ 5%;

◆ BF-type electrical safety design and 100-240v wide voltage input design;

◆ Forward and reverse speed, manual / foot control, voice prompts of switch and reversal;

◆ Warning and fault alarm of torque overload;

◆ Real-time display of operational parameters;

◆ Grinding and expansion functions (straight and curved shank handle);

◆ Power-drive handle with the quick stop function of 0.2 S at work;

◆ ISO-E quick-change interface.

POWER HANDLE [ HDS01 ]

◆ Cable length of 4M,ISO-E quick-change interface,disinfection at high-temperature and pressure (cable included)

◆ Peak output power of 200W, output torque of 3.35N.cm, with rotational speed as high as 60000r/min;

◆ Light in weight, small vibration, small temperature rise, low noise ≤ 60dB, the maximum working temperature≤ 50 ℃.

Foot Switch [ HJ01 ]

◆ Cable length of 4M, stepless speed change device, and speed reversal can be conducted through the foot switch;

◆ Waterproof grade of IP8X, anti-slip and anti-rollover;

◆ Stylish, solid and reliable structure, bearing the maximum limit of 1350N (138Kg), comfortable and durable;

Drill Bits Handle [ HZS01 ]

◆ Light alloy materials, surface treatment of anti-corrosion and anti-wear, disinfection at high temperature and pressure;

◆ Small and exquisite design structure, comfortable holding, strong operability;

◆ Have direct plug-in and locking functions together with power handle, avoiding being dropped at work;

◆ Working speed of 0-1900r / min, stepless speed change device; low temperature rise, small vibration, low noise, with no-load noise <75dB at maximum speed;

◆ Output working torque of 880mNm.

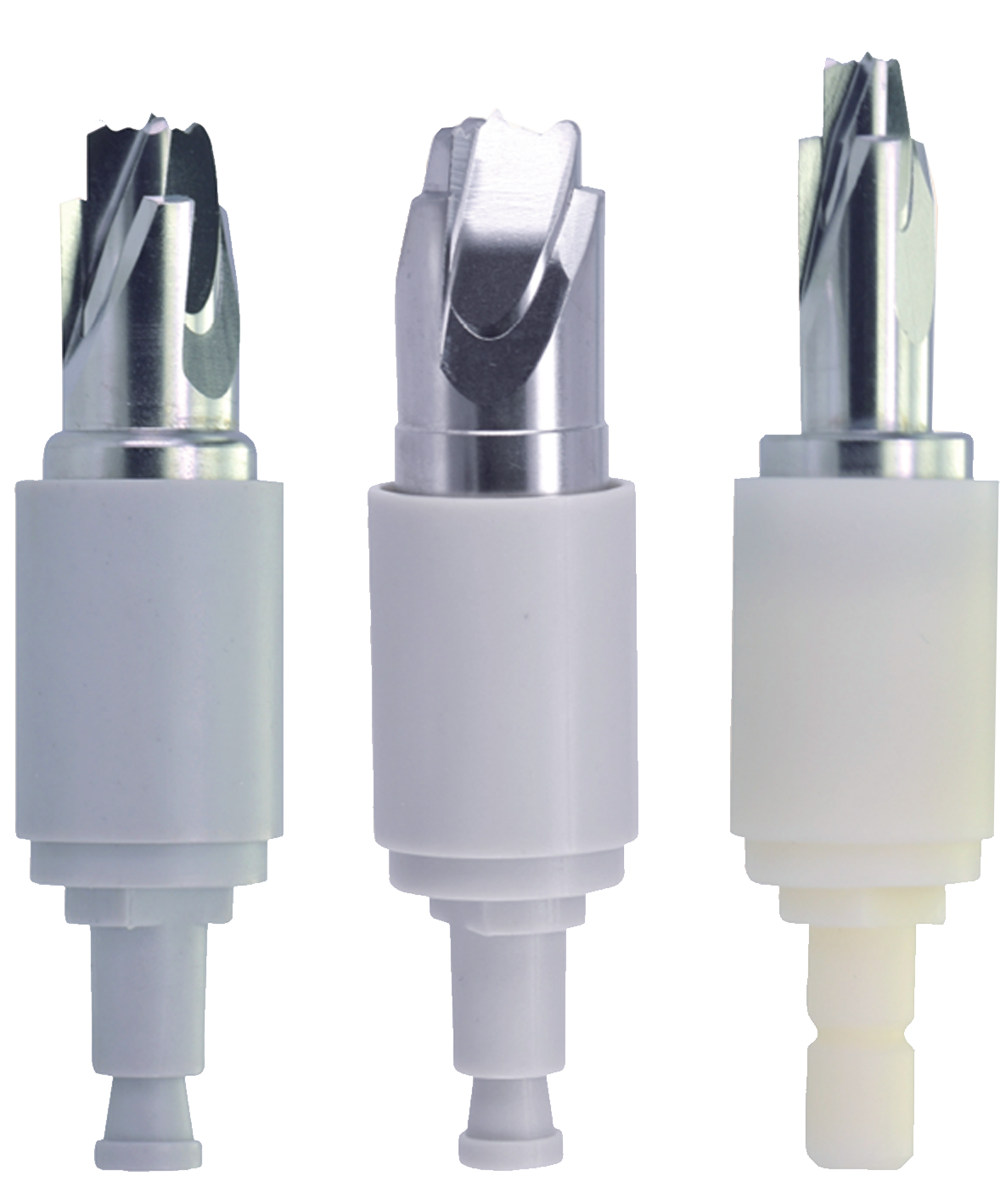

Drill Bits [ HZ-I ]

Functional features Automatic stopping with bone thickness above 3 mm Combination of drilling and milling, double insurance, safe and reliable; One-step cutting with no bone flap residues; Avoid repeated sterilization, cross-infection and postoperative cleansing; Reduce preparation time for emergency treatment; Prevent massive sinus bleeding.

Milling Cutter Handle [ HXS01 ]

◆ Light alloy materials,surface treatment of anti-corrosion and anti-wear, disinfection at high temperature under high pressure.

◆ Small and exquisite design structure, comfortable holding, strong operability;

◆ Have direct plug-in and locking functions along with power handle, avoiding being dropped at work;

◆ Working speed of 0-60000r / min, stepless speed change device; low temperature rise, small vibration, low noise, and no-load noise <75dB at maximum speed;

◆ Meningeal sheath design, effectively protecting the brain tissues from damages caused by high-speed milling cutter, and improving surgical safety;

◆ Fixed directions design of rotating protective sheath, reducing the brain tissue damages caused by the rotation of the protective sheath;

◆ Quick loading and unloading structure design for milling cutter, and the milling cutter in the groove can be used without pressing, saving the preparation time for surgery;

◆ A complete range of specifications.

Milling Cutter [ HX-I ]

One-time use, avoiding cross-infection; High hardness and sharp cuttings; A complete range of models and specifications, which can be matched with a variety of international and domestic equipment. Sterilization packaging, reducing preparation time for surgery;

Straight/Bending Burrs Handle [ HMZS01 /2/3 & HMWS01 /2/3 ]

◆ Light alloy materials, surface treatment of anti-corrosion andanti-wear, high disinfection at high temperature and pressure;

◆ Small and exquisite structure design, pen-shaped holdingwith an angle of 20 °, comfortable holding, strong operability;

◆ Have direct plug-in and locking functions together with powerhandle, avoiding being dropped at work;

◆ Working speed of 0-60000r / min, stepless speed change device, low temperature rise, small vibration, low noise with no-load noise <75dB at maximum speed;

◆ A variety of straight and curved handles available;

◆ A complete range of specifications.

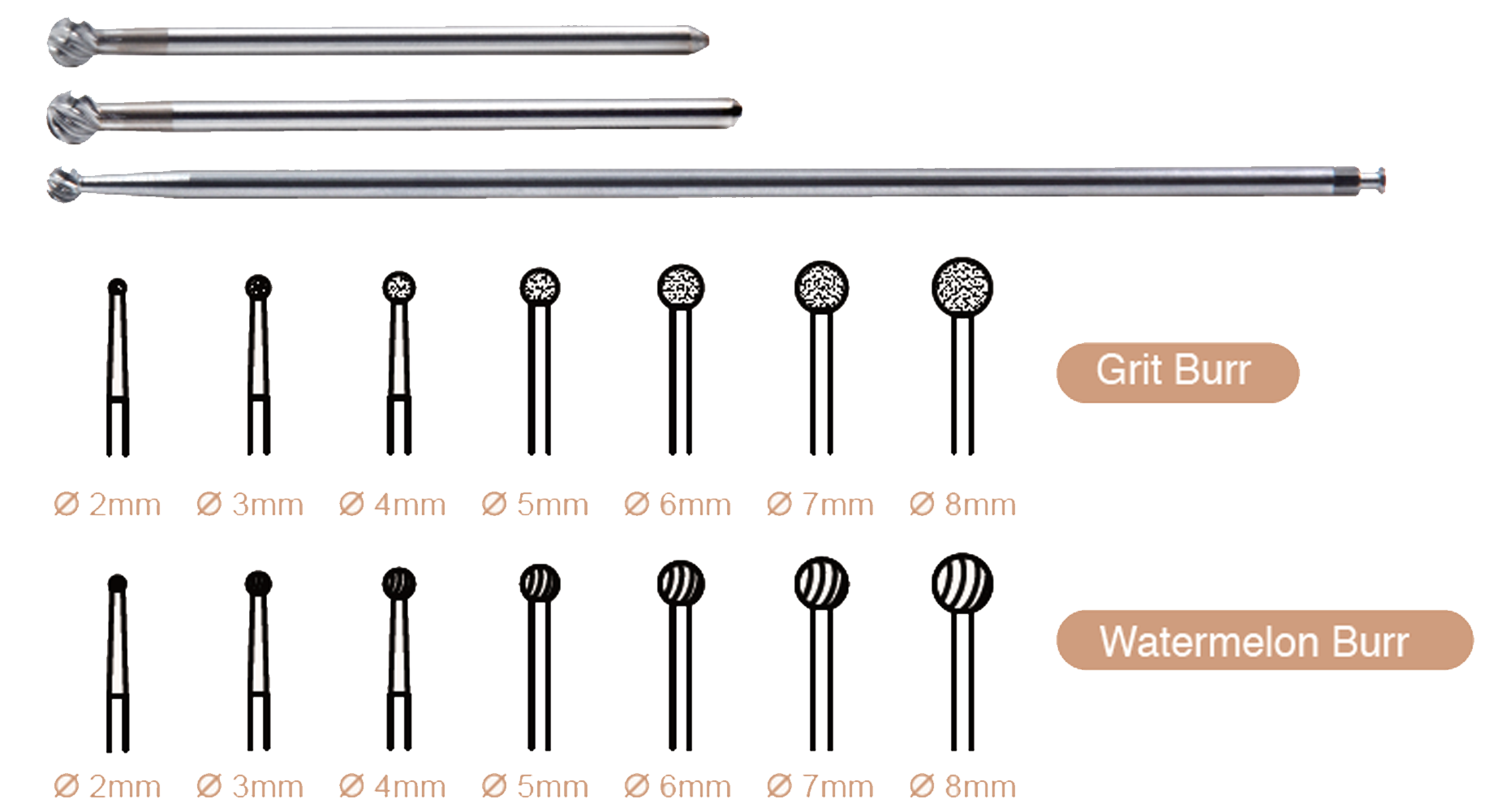

Burrs [ HM-I ]

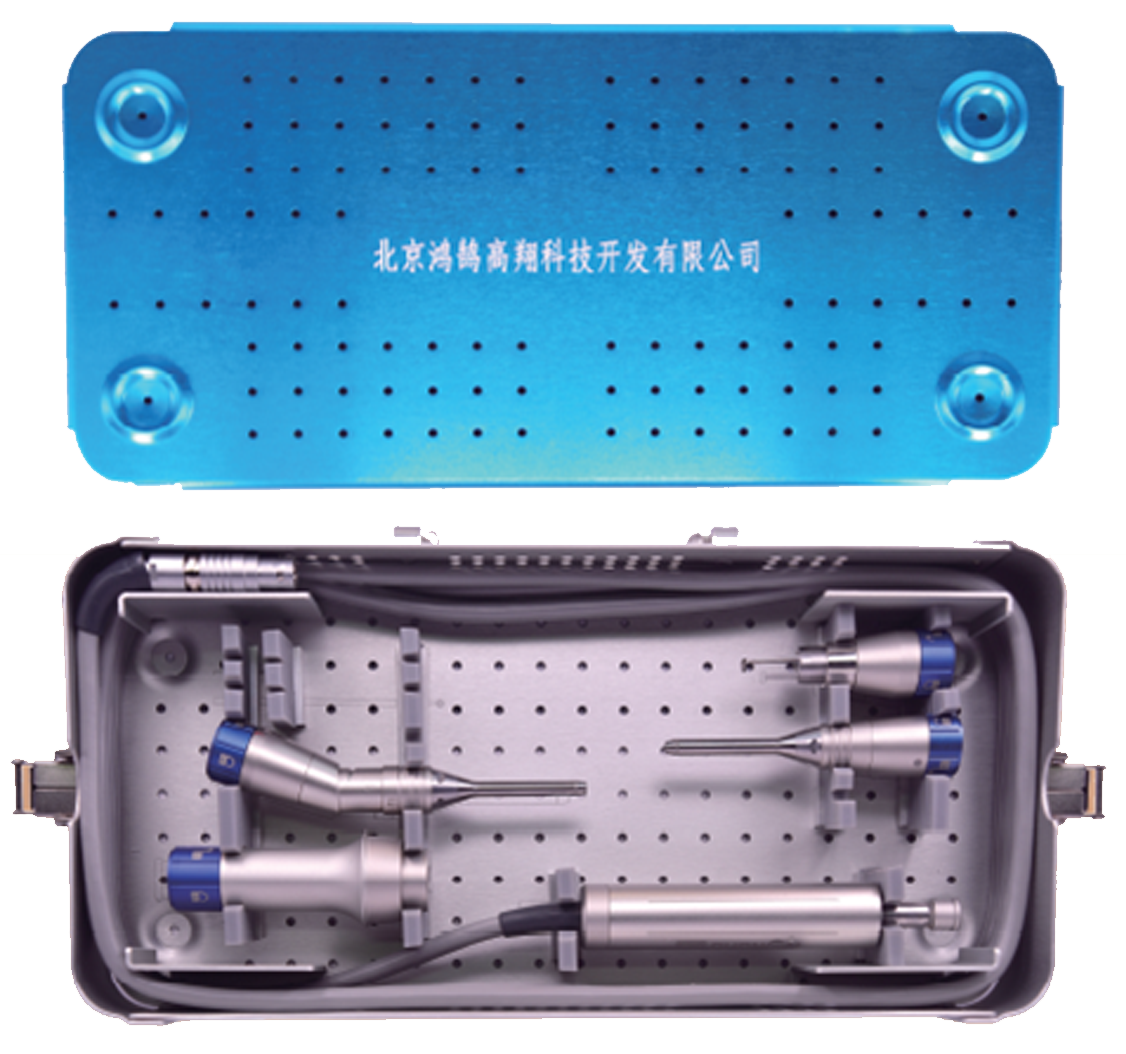

Sterilization Box [ HXDH01 ]

Example Text